The Recipe For Precision Parts Processing Recipes: It Only Takes 1 Second To Start Cheating, Allowing Ordinary Girls To Transform Into Advanced Skills

Precision Parts Processing is an industry that integrates high-precision technology CNC metal, advanced equipment and exquisite craftsmanship. It requires precisely manufacturing of parts in the micron or even nanometer range to meet the needs of high-precision components in industries such as aerospace, medical equipment and precision instruments.

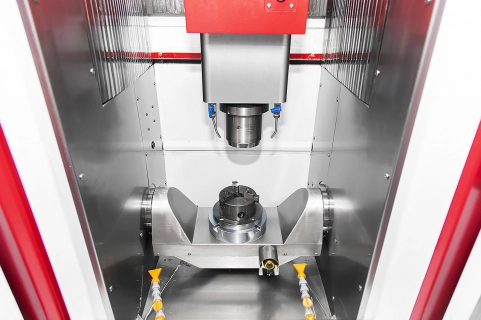

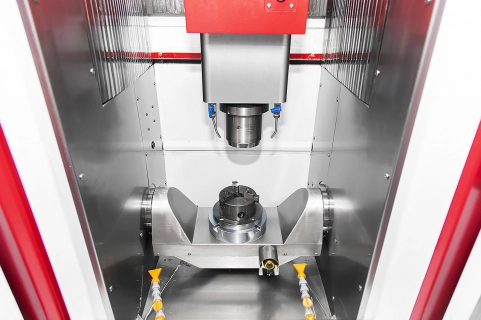

In this industry, computer CNC (CNC) technology plays a central role. By programming, CNC machine tools can automatically process complex parts based on preset paths. This automation not only improves productivity, but also greatly reduces the possibility of human error. With the development of technology, the use of multi-axis interlocking technology makes the processing process more flexible and can handle more complex workpiece designs.

In addition to advanced equipment, precision machining technology is also the key to ensuring part quality. For example, ultra-precision cutting technology can complete the machining with minimal cutting force, thereby reducing part deformation and tool wear. In addition, non-traditional treatments such as electrochemical processing (ECM) and laser processing also occupy the precise processing position, which eliminates materials without mechanical pressure and is suitable for cement carbides and other difficult-to-process materials. Exquisite processing.

Precision parts machining is not without its challenges. Changes in materials, ambient temperatures, and slight differences in thermal stability of the machine tool may affect the machining accuracy of the parts. Therefore, it is crucial to maintain a clean room environment with constant temperature and humidity and perform thermal error compensation on the machine tool. At the same time, in order to ensure the quality of processing, regular calibration and maintenance of machine tools are also an indispensable task.

In terms of quality management, the concept of total quality management (TQM) is widely used throughout the process. Every link from the entry of raw materials to the export of finished products is strictly inspected and controlled. In addition, various high-precision measurement tools, such as three-dimensional measuring machines and optical projectors, are used to inspect the finished product to ensure that each product meets the design specification requirements.

It is worth mentioning that with the rise of industry 4.0, intelligent manufacturing has become a new trend in the precision parts processing industry. By applying technologies such as the Internet of Things, big data analysis and machine learning, smart factories can achieve self-optimization of the production process and further improve processing accuracy and efficiency.

The precision parts processing industry is a highly specialized and technology-intensive field. Whether in equipment selection, processing technology or quality control, strict control is required. As technology continues to develop, the future of the industry will become brighter, and it also lays a solid foundation for the development of related industries.

In the future, we have reason to believe that precise parts handling technology will continue to break through new limitations and continue to push the modern industry to higher accuracy and complexity.