An In-depth Analysis of CNC Turning Shops Quote for Evaporator Production Amid a Dusty Production Environment

The choice of materials for evaporator production is crucial. Different applications require different materials based on factors such as the operating temperature, the type of fluid being evaporated, and the

Unveiling the Intricacies of CNC Machining Quote for Toy Guns and the Significance of Science Popularization in This Realm

Science popularization plays a vital role in the realm of CNC machining and toy gun production. By educating the public about the manufacturing processes involved, people can gain a better understandin

Exploring the Excellence of a china CNC Machining company: Specializing in High-Quality Water tanks with Advanced electron beam engraving Technology

In the ever-evolving world of manufacturing, a china CNC Machining company stands out as a key player. These companies combine precision engineering, cutting-edge technology, and a commitment to quality to deliver out

Unveiling the World of Cheap CNC Prototyping and the Significance of Cross Shaft in Marketing Strategies for Innovative Product Development

One of the key advantages of cheap CNC prototyping is its ability to provide rapid turnaround times. Traditional prototyping methods often involve lengthy and complex processes that can take weeks or even months. In contrast, CNC pr

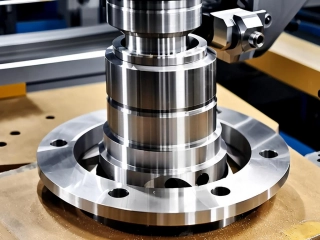

Discover the Excellence of the Top CNC Milling Manufacturer: Precision Machining with a Focus on Oscillator Tube Production and Overcoming the Challenges of Rough Milling

Rough milling can occur due to a variety of reasons. One of the main causes is improper tool selection. Using the wrong type or size of cutting tool can lead to uneven cutting and a rough surface finish. An

An In-depth Inquiry into CNC Miling Shops Regarding Pinion Gear Production and the Impact of Unstable Air Pressure

Quality control is of utmost importance in CNC milling shops when producing pinion gears. To ensure the highest quality, these shops employ various inspection and testing methods. One common method is the

Exploring the Synergies between Robotics CNC Machining, Power Supply, and Warehousing and Logistics in Modern Industrial Operations

These systems can be easily reprogrammed to produce different parts or components, making them highly adaptable to changing market demands. Manufacturers can quickly switch production lines without the need for

Exploring the Excellence of CNC Titanium Products with a Focus on Vehicle Hinges and the Significance of Plane Measurement

CNC Titanium vehicle hinges are designed to offer smooth operation with minimal friction. The precision machining of titanium components results in a smooth surface finish, reducing the resistance between

Exploring CNC Turning Factories Inquiry, the Significance of Juicer Chute, and the Importance of Corner Cleaning in Manufacturing Processes

Quality control is of utmost importance in CNC turning factories. The factory should have strict inspection procedures in place to ensure that each part meets the required standards. This may involve using advan

An In-depth Analysis of china CNC Miling manufacturers: Focusing on Fabrication Parts and Dealing with System failure Challenges

In conclusion, china CNC Miling manufacturers have made significant strides in the field of CNC milling, producing high-quality Fabrication Parts that meet the demands of global industries. While they f

Exploring CNC Machining near me: The Significance of Oscillator Tube and the Impact of Chaotic Enterprise Management on the Industry

The quality of the Oscillator Tube directly impacts the performance of the CNC Machining equipment. A high-quality Oscillator Tube will provide a stable and accurate signal, resulting in precise machining operation

Discover the Excellence of the top CNC prototyping shop: Unveiling the Significance of Radio antenna Prototyping and the Role of the Supervision Mechanism in Ensuring Precision

When prototyping Radio antenna, several factors need to be taken into account. These include the frequency range, gain, radiation pattern, and impedance matching. The design must also consider the physical environment in which the

To address the problem of rough milling, the top CNC milling manufacturer employs several strategies. First and foremost, they carefully select the appropriate cutting tools based on the material and geometry of the workpiece. They also optimize the cutting parameters through extensive testing and analysis to ensure the best possible surface finish. In addition, they use advanced coolant systems to reduce heat generation during milling, which helps to prevent tool wear and improve the quality of the machined surface. Another approach is to use multi-step milling processes, where roughing and finishing operations are separated to achieve a smoother final surface.